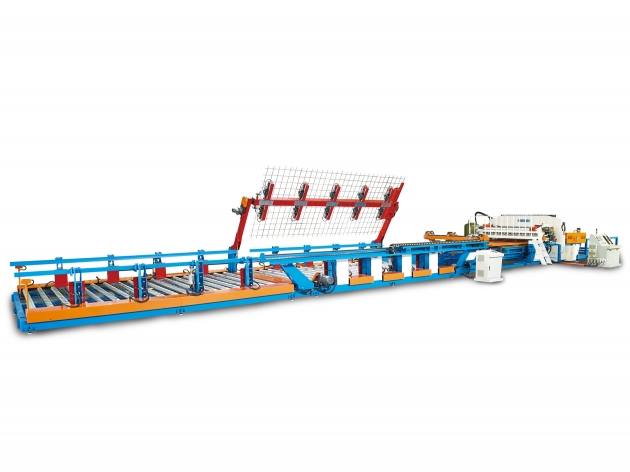

Column Type Multi-spot

Mesh Welding Machine

Mesh Welding Machine

Merchandise number:MODEL:CTC-2500-6TR

-

Column Type Multi-Spot Welding Machine(A Type)

Country of Origin:Taiwan

Model:CTC-250-6TR (A Type)

Detail Specifications

* Taking mesh by operator for last operation phase

* The longitudinal & cross wires must be straighten and pre-cut.

-

Column Type Multi-Spot Welding Machine

Model:CTC-250-6TR (B Type)

Detail Specifications

* Last Connection Auto Mesh Collecting Machine

* The longitudinal & cross wires must be straighten and pre-cut.

-

Column Type Multi-Spot Welding Machine

Country of Origin:Taiwan

Model:CTC-250-6TR (C Type)

Detail Specifications

* Rear stage connection- Automatic Net Collection+Flipping Machine

* The longitudinal & cross wires must be straighten and pre-cut.

-

A Type

-

B Type

-

C Type

Delivery Lead Time:180days

A. Brief introduction of machine structure

1. 150KVA×6 sets transformers

2. Power source:380V/50Hz

3. Power 3-phases input power source (Alternating current A.C)

4. Power input is 3-phases and is evenly divided for 6 sets of transformer

5. Power (electricity) input for each set of transformer is single phase

B. The structure description:(divided into 5 sections)

1. Sec. 1:50sets of coil wire feeding coiler

2. Sec. 2:50sets of wire straightening wheel

3. Sec. 3:Main frame base of the welding machine

4. Sec. 4:Cross wire auto discharge stand

(cross wire shall be preset with length to be cut)

5. Sec. 5:Last machine connects automatic hauling machine

C. The specification of the whole set of welding m/c.

1. Coiler material feed stand:50sets

2. Total length of the machine:30M

3. Total width of the machine:3.3M

4. Total height of the machine:2.2M

5. Welding position height:1050mm

6. Total weight:12T

7. Required square measure space out from workshop:overall production line

Length 30M×Width 12M

D. Welding capacity

1. Set with 25 sets of welding cylinder all in all (Ø90×80×1 sections)

2. 6 sets of transformers will work with 25 pcs of welding cylinders to descend and welding altogether.

3. Widest mesh:2500mm

4. Wire diameter:Ø3~Ø10mm(平網)﹐Ø4~Ø5mm(捲網)﹐60 iron wires can be welded per minute.

5. Space (pitch) for vertical wires:50~100~150~200mm

6. Space (pitch) for cross wires:50~300mm

E. Requested apparatus (peripheral equip) which shall be prepared by buyer itself.

1. Compressor:50HP

2. Cooling water:30T

3. Power consumption volume:500Amp

4. 500Amp No fuse cut out switch

5. Freezing type drying-device