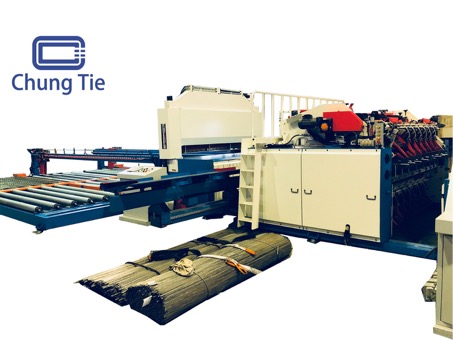

CTC-250-AC-6TR -Double-Column Type Multi-Spot Welding Machine

Merchandise number:CTC-250-AC-6TR -Double

- With Double-Layer welding, the output can be upgrade almost 1/3 than traditional welding machine. (Actual data will depending on operating conditions)

- 250KVA × 6 sets transformers

- Power source: 380V/50Hz

- Power 3-phases input power source (Alternating current A.C)

- Power input is 3-phases and is evenly divided for 4 sets of transformer

- Power (electricity) input for each set of transformer is single phase

B.) Welding (soldering) method

- Overall 24 sets of “Welding Cylinder” (Ø90×80×2 sections)

- There are 6sets of transformers and 24 sets of welding cylinders to be descending together and welding; there are three welding methods:

- 24 sets of welding cylinders to be descending together and welding at a time.

- 24 sets of welding cylinders to be descending together and jumping 123456 for discharge separately.

- 24 sets of welding cylinders to be descending together and jumping3〜4、2〜5、1~6

- Weld mesh length: 6000mm

- Weld mesh width: 2400mm

- Diameter of wire: Ø4~Ø8mm

- We will install voltage stabilizer inside the control box.

- Straight line pitch: 50~100~150~200~250~300

- Send the material by means of motor to the position where the material shall be welded. (The length of straight line tip can be set with the dimension so that meshes of many specifications are all workable & feasible.

- Transverse line pitch: 50~1000 mm.

- Transverse line automatic material putting/feeding stand: The iron transverse lines will be arranged in order after being put inside

- Material putting/feeding stand can automatically put transverse line to the place where it shall be welded piece by piece. There is one proximity switch detecting device

- Standard capacity of transverse lines material holding stand, which is connected under material putting stand. (About 500kgs)

D.) Analysis Of Machine Structure:

- Coil Wire Feeding Stand 30 Sets

- Straight Wire Straightening Wheel 30 Sets

- Main Double Welding Base

- Automatic Cutting Machine

- Delivery Wire Mesh

E.) welding speed ﹕Wire Dia. Ø6mm, Normal speed 80pcs/minute Up.

Ø12mm Speed 50pcs/minute.

F.) To accomplish the welding

- Transverse line pitch material-pulling: by CNC serve motor

- The pitch of whole mesh: can be welded with different dimensions

- 15 sorts of specification & dimension can be memorized inside the formula

- Standard slide of machine construction is 6M long

G.) Automatic Cutting Machine

- Automatic Cutting Machine will be operation by two Hydraulic cylinder core and Nitrogen.

- The Core Spec will be Ø100 x 280 stroke x 2 set

- The speed of Automatic Cutting Machine: Only need 1Sec/ one cutting

- Oil Tank Spec: 1100x950x500 and with one 15HP Motor.

- We use Nitrogen to save the pressure, when Automatic Cutting part need to cut wire mesh, the Nitrogen will release the pressure, with 15HP Motor, together push the Hydraulic cylinder to cutting wire mesh, to achieve a high speed cutter.

- When the automatic cutting machine cuts, welding machine continues to weld, achieve fully automatic.

H.) Welding machine zone, raw material zone and square measure of finished products

- Square measure of welding M/C: width 8M×Length 30M

- Square measure of raw material zone: width 5M×Length 30M

- Square measure width of finished products: width 8M×Length 30M

I.) Request equipment on Buyer’s site

- Compressor:50HP

- Freezing type drying machine 1 SET( Suits for the usage of 50HP air compressor)

- Cooling water:30T

- Power consumption:600Amp

- 600Amp No fuse cut out switch

- The usage of machine norm

A. The temperature of cooling water shall be kept under normal temperature.

B. Pay heed to the screws locating in the “Lubrication oil pump” and all moving places of one whole set of machine not to get loose & unfastened.